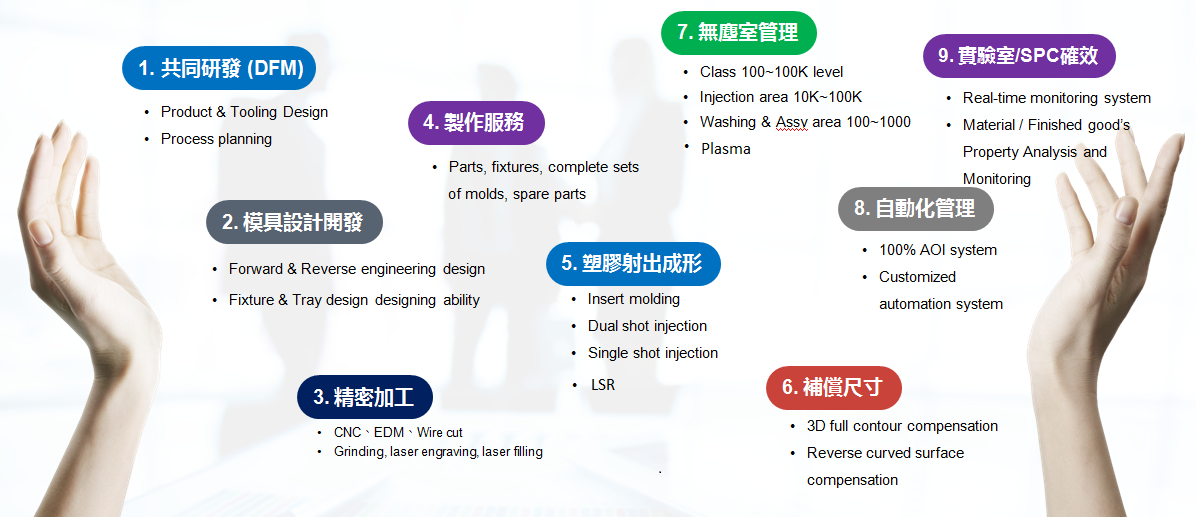

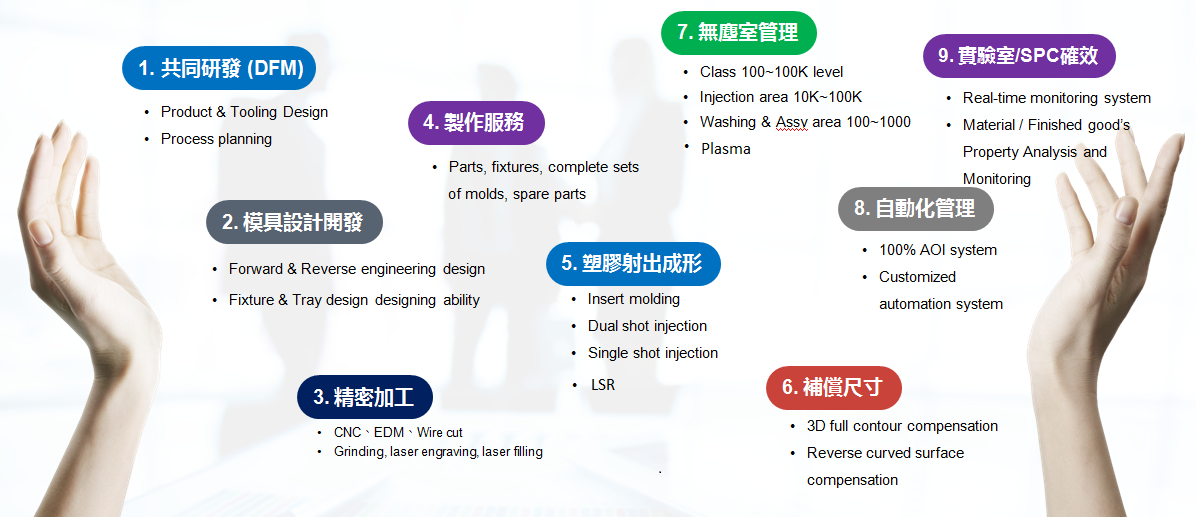

- Design Engineering Planning

| 3D CAD/CAM Design System |

Tooling design module , components build in and customize program,

2D/3D components data base. CAE & CAM two-way interface connection. |

|

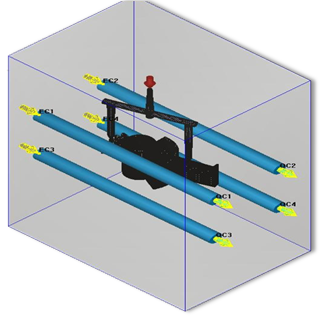

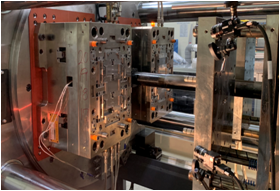

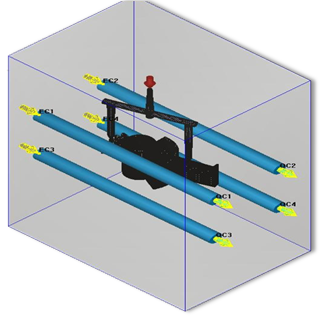

| Mold Flow Analysis |

Utilize the analysis software to predict the problem upfront then solve in the beginning, in order to shorter the tooling lead time. |

|

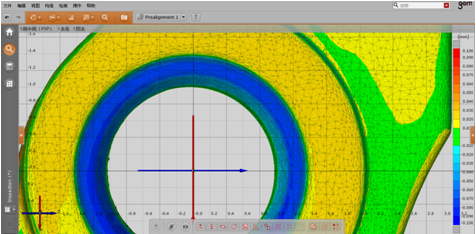

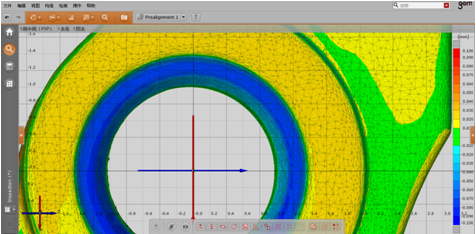

| Reverse Engineering System |

◆ Finish Good: Rapid surface creation>arc surface construction> solid configuration> Synchronize build up

◆ Compensate: Scanning > mirror> rapid arc surface>compensate and covert to core/insert |

|

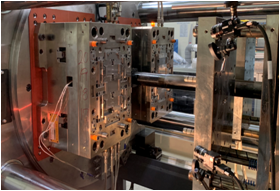

- Min Aik focuses on mold-related technology research and development, pays attention to product precision, has rapid mold design, manufacturing and maintenance capabilities, so that each process is completed in house, using computer-aided software to improve production, reduce the number of mold trials, and shorten the mold Development cycle to reduce mold manufacturing costs. Processing machine:

Mitsubishi EDM:

High precision / high speed / low consumption processing

Pitch / shape accuracy +-0.003mm

Surface roughness Ra 0.8μm

Product introduction (mold, mold parts, fixtures)

Product introduction (mold, mold parts, fixtures)

- Specialized in molds, machining parts, fixture development

|

|

|

|

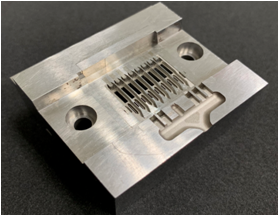

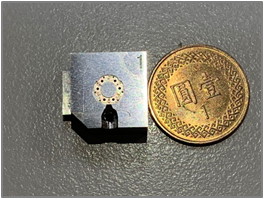

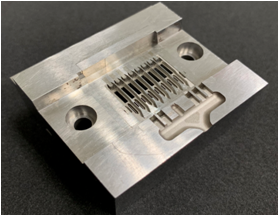

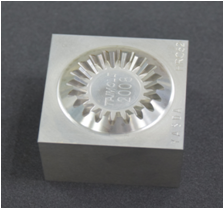

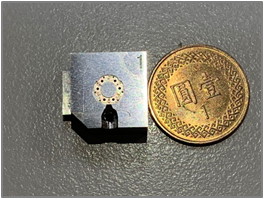

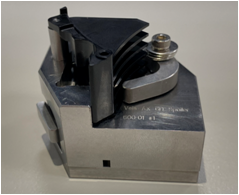

| Multiple sliced insert |

Hard disk high precision embedded component’s sliced insert

|

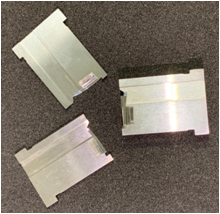

Various shape mold machining

|

|

|

|

|

|

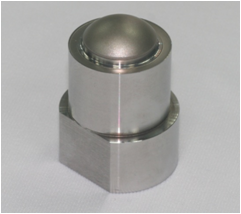

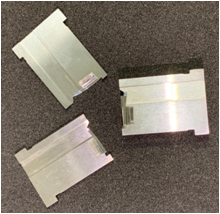

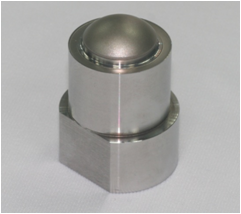

| Various shape mold machining |

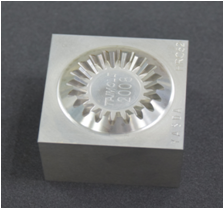

Lens module |

High-precision fixture manufacturing Optical |

|

|

|

|

|

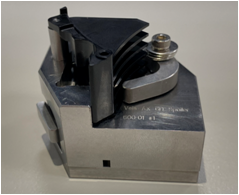

| High precision mold machining |

Automation used fixture |

|

|

Product introduction (plastic injection product)

- The parts is install in a hard disk (HDD) which is using a precision mold machining technology and a large amount of engineering technology to produce precision molded products for customers。

- We provide process set up/Shipping tray, Optical/Medical and 3C industries。

|

|

|

|

| Hard disk high precision insert molding component |

Hard disk component |

Hard disk component |

|

|

|

|

|

| Dual shot 3C product |

Medical dual shot kit |

Various product structure design |

|

|

|

|

|

| Automation used IM tray |

contact lens of PP blister |

|

|

Senior Sales Manager 黎先生 Afang.Lee

Office: +886 2 8200 1008 #1505

FAX: +886 2 8200 1012 #1505

Email: Afang.Lee@minaik.com.tw

Product introduction (mold, mold parts, fixtures)

Product introduction (mold, mold parts, fixtures)